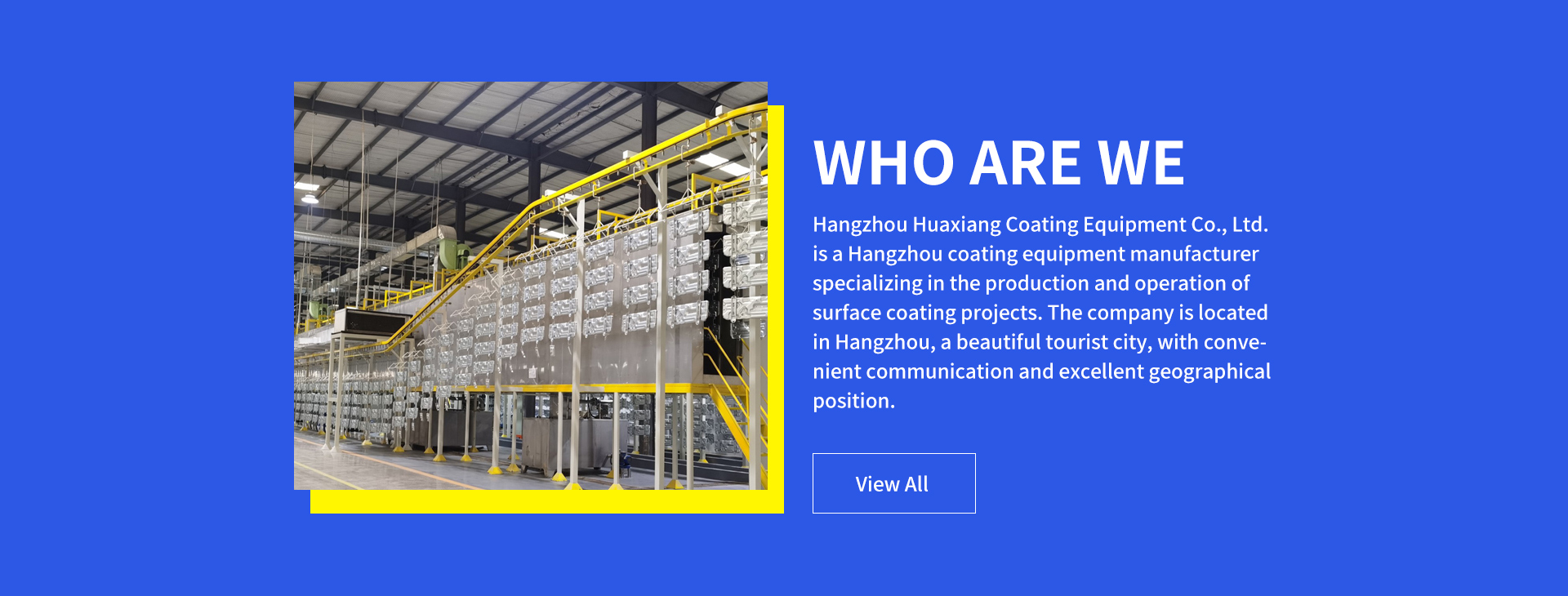

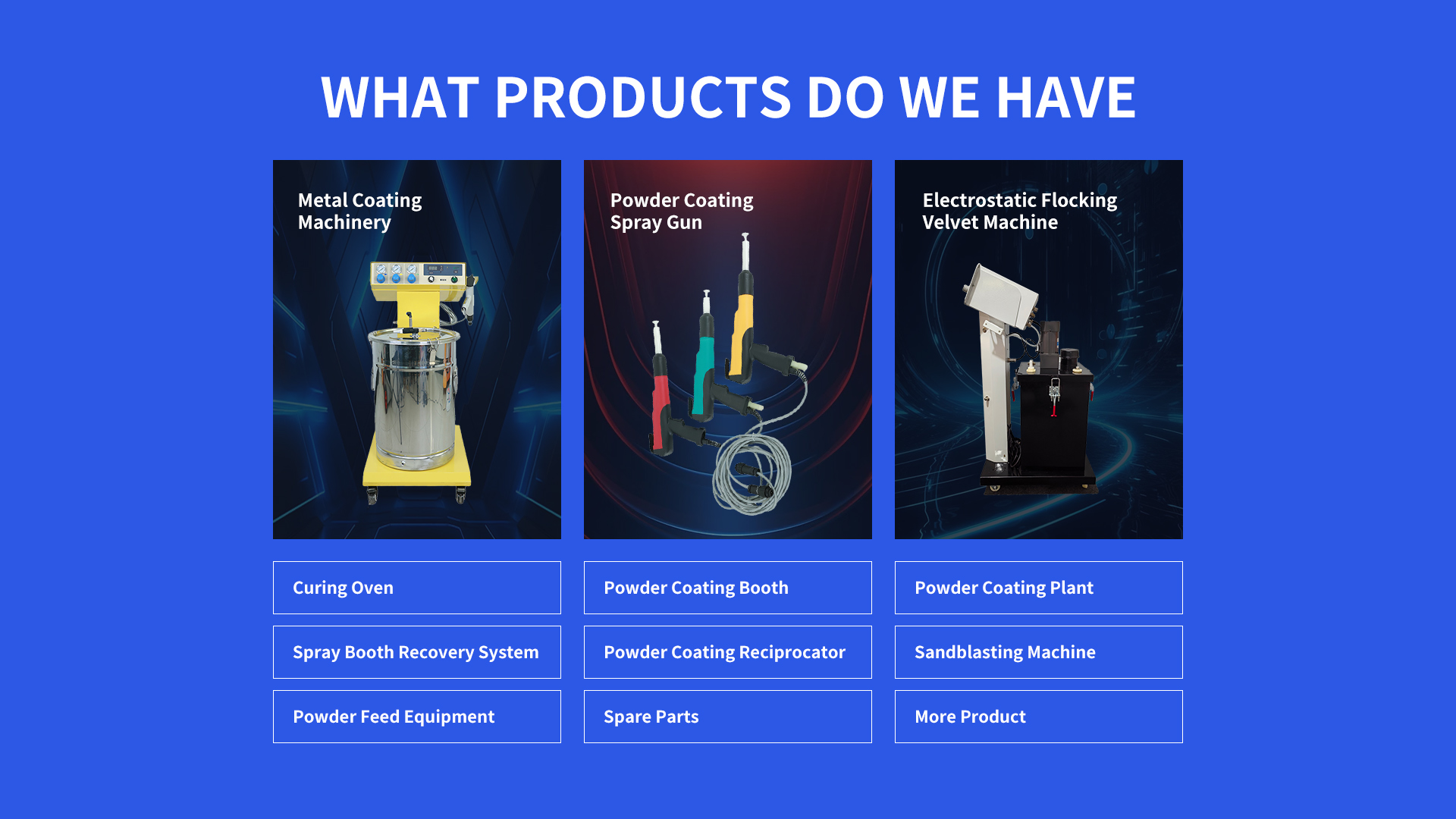

1. Introduction and Structure of Powder Coating Production Line Suppliers' EquipmentPowder Coating Production Line Suppliers provide systems that are integral for efficient coating. These lines mainly include a conveyor mechanism for moving workpieces steadily. The powder coating booth is equipped with advanced spray guns, enabling precise powder application. The curing oven comes with accurate temperature regulation for proper powder fusion. Moreover, powder recovery devices and intelligent control panels are essential parts, facilitating powder recycling and seamless line operation.

2. Application Scenarios of Powder Coating Production Line Suppliers' Equipment

The equipment from these suppliers is applicable in diverse industries. In the aerospace field, it coats aircraft parts for corrosion resistance and enhanced performance. For metal construction companies, it provides durable finishes for structural elements. In the home appliance manufacturing industry, powder coating production lines are used to coat metal parts of appliances, ensuring protection and an appealing look.

3. Price of Powder Coating Production Line Suppliers' EquipmentThe cost of equipment from

Powder Coating Production Line Suppliers varies. Entry-level lines suitable for small-scale businesses may start at around $25,000. Mid-range lines with better features and higher production capacity can cost between $40,000 and $80,000. High-end, large-scale production lines with cutting-edge technology can be priced over $80,000.

4. Correct Usage Method of Powder Coating Production Line Suppliers' Equipment

Start by loading workpieces properly onto the conveyor. Adjust the spray gun settings, such as powder flow and electrostatic charge, according to the powder characteristics and workpiece needs. Preheat the curing oven to the right temperature. Continuously monitor the coating process as workpieces pass through the line and make timely adjustments. Once the curing is done, unload the workpieces carefully.

5. How to Select Equipment from Powder Coating Production Line SuppliersWhen choosing equipment from

Powder Coating Production Line Suppliers, consider your production scale and product variety. Look for suppliers with a proven track record of quality and reliable after-sales support. Evaluate the line's throughput, the efficiency of the powder recovery system, and the stability of the control panel. Also, check if customization options are available to meet your unique requirements.

6. Safety Precautions of Powder Coating Production Line Suppliers' Equipment

Safety is of utmost importance. Workers should wear appropriate protective gear, including masks, gloves, and safety glasses, to prevent powder inhalation and skin/eye damage. Ensure adequate ventilation in the powder coating booth to avoid powder dust buildup. Regularly check the electrical systems and keep combustible materials away from the production line.

7. Rationality Analysis of Powder Coating Production Line Suppliers' EquipmentInvesting in equipment from

Powder Coating Production Line Suppliers makes sense. It boosts production efficiency, cuts down on labor costs, and guarantees consistent coating quality. The powder recovery system helps reduce material waste, saving costs in the long run. The advanced design of the line allows for adaptability to different production demands.

8. Q&A about Powder Coating Production Line Suppliers' Equipment

Q1: Can I upgrade the equipment from powder coating production line suppliers?

A: Yes, many suppliers offer upgrade options. You can upgrade components like spray guns or control systems to enhance the performance of your powder coating production line equipment.

Q2: How does the powder recovery system of the equipment from powder coating production line suppliers work?

A: The powder recovery system uses filters or cyclones to separate powder from the air in the booth. The collected powder is then reused, minimizing waste and saving costs for the powder coating production line equipment.

Q3: What's the difference between basic and high-end equipment from powder coating production line suppliers?

A: High-end equipment offers better precision in coating, faster production speeds, more advanced control features, and higher durability. Basic equipment is more suitable for simple and small-scale applications of powder coating production line equipment.

Q4: Is the installation of equipment from powder coating production line suppliers difficult?

A: Installation complexity varies. Some suppliers provide detailed installation guides and even offer installation services. Smaller lines may be easier to install, while larger, more complex powder coating production line equipment might require professional installation.

Q5: How often should I replace the filters in the powder coating production line equipment from suppliers?

A: The frequency of filter replacement depends on usage. Generally, it's advisable to check and replace filters every 2-3 months to maintain the efficiency of the powder coating production line equipment.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com